Lab Analysis of Customer Samples

WE DO YOUR TESTING FOR FREE!

All you have to do is ship it to our lab and we take care of the rest

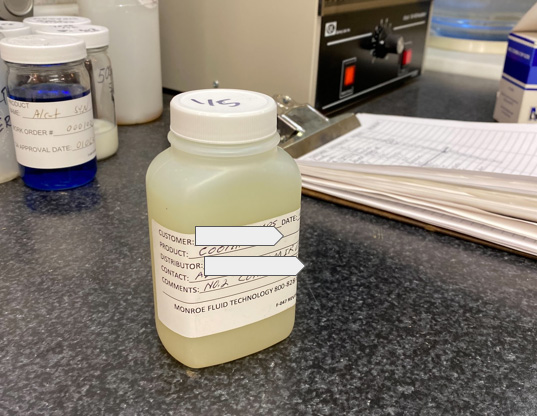

Step 1: Receipt and Logging

Information provided by the end user is entered into the log (ex. machine no., product used, contacts, date etc.)

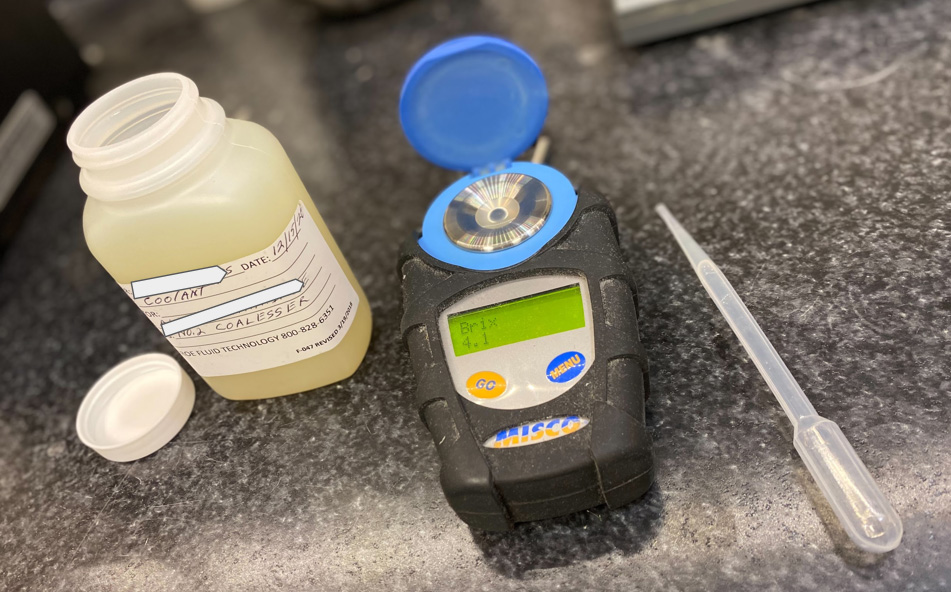

Step 2: Determine Concentration

After Logging, we use a digital refractometer to measure Brix to then calculate the coolant concentration.

Concentration is the most important factor in maintaining a coolant’s health.

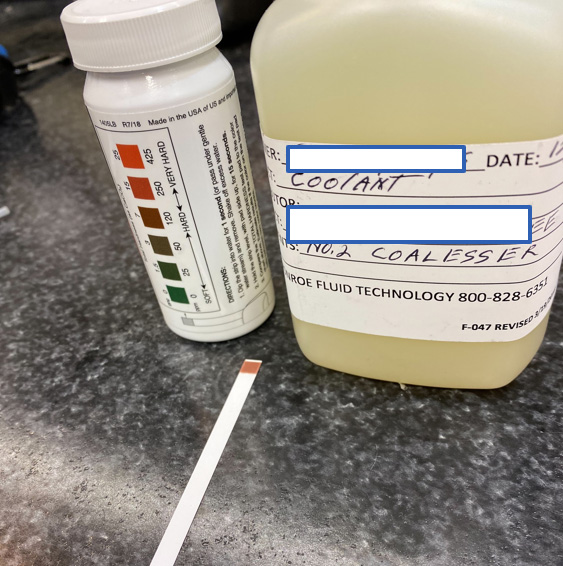

Step 3: Checking Water Condition

Water hardness is determined by a test strip dipped in the coolant. This is then compared against a color gradient chart.

High water hardness can affect coolant stability and corrosion resistance.

Different parts of the USA have different water hardness and quality. It’s a good practice to send a sample of your water to our lab to determine if any adjustments need to be made to ensure proper coolant performance.

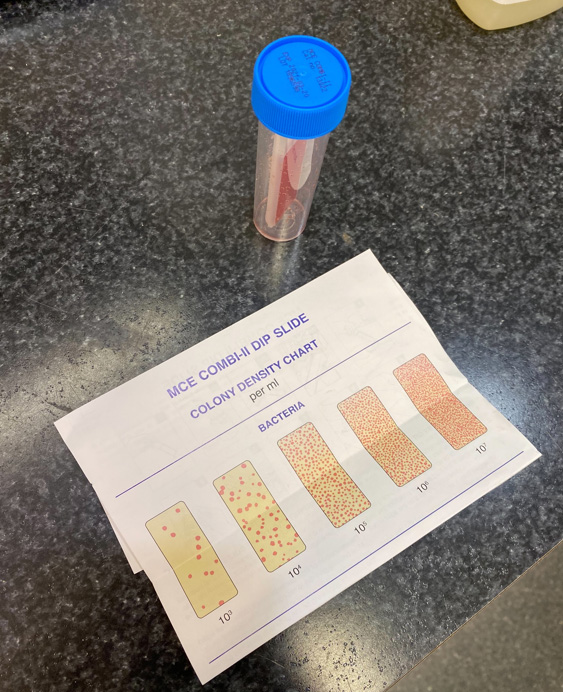

Step 4: Bacteria/Fungal Testing

Bacteria and fungi feed on the coolant degrading its quality and condition, fungal growth can clog lines and impede coolant flow/delivery.

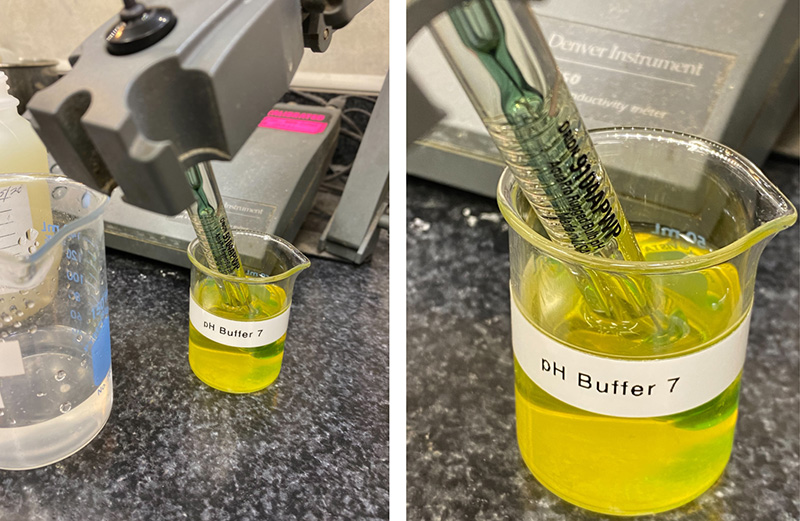

Step 5: Measure pH

pH can provide a good indication of over all coolant condition.

Step 6: Coolant Analysis Report

We encourage all of our customers to send samples, as the data can illustrate trends and timely information that will allow a timely response if a problem is developing. It is less expensive to maintain the coolant than it is to pay for cleaning, disposing and then recharging a system, not to mention the cost of the downtime of the machine and the expense associated with a change out. Customers regularly sending samples will be able to see the trends as they develop a history of the coolant condition.

Coolant Analysis Report

This is an example from a customer with a central system. Samples are obtained weekly and sent to our lab. Customers with individual sumps can send samples for analysis and we will generate the same type of report if you want to track coolant in each of your machine sumps. We highly recommend our end users to take advantage of this free service. Save money, get better performance, extend tool life and reduce cost per part by monitoring coolant condition.

Postscript on Importance of Coolant Concentration

It literally takes about a minute to use a refractometer-digital or the sight glass models. Every Coolant, regardless of manufacturer, has its own Brix index. The reading of the Refractometer is then multiplied by the particular coolant Brix Factor (on every coolant label). To make the conversion easy, we have developed a Coolant Concentration Calculator that is on our web site at www.monroefluid.com. You simply choose the product, enter the Brix reading and the percentage is produced. Anecdotally, about 90% of coolant quality issues are directly related to coolant concentration.

We strongly suggest to our customers to take advantage of our free sample analysis. If you have any questions, feel free to contact us at 1-800-828-6351 our Lab and Technical Support Team are standing by to assist you.